1, Technical Specification:

|

Item

|

Unit

|

WDCL-30B

|

WDCL-30BH

|

|

Traver |

|

|

|

|

Max.swing Dia. over

bed

|

mm

|

Ø600

|

Ø600

|

|

Max.cutting Dia. for disc

parts

|

mm

|

Ø500

|

Ø400

|

|

Max.cutting Dia. for axle

parts

|

mm

|

Ø320

|

Ø320

|

|

Maximum cutting length (chuck

end face to dead center)

|

mm

|

1000

|

900

|

|

Distance from spindle center

to ground

|

mm

|

1150

|

1150

|

|

Max.travel for axis

X

|

mm

|

270

|

270

|

|

Max.travel for axis

Z

|

mm

|

1060

|

1060

|

|

Spindle

|

|

|

|

|

Spindle nose

|

|

A₂-11

|

A₂-11

|

|

Spindle bore

|

mm

|

Ø105

|

Ø105

|

|

Spindle drive mode

|

|

belt drive

|

belt drive

|

|

Max. spindle speed

|

rpm

|

1600

|

1600

|

|

Spindle motor

power

|

kW

|

22

|

18.5/22

|

|

Spindle front end

Dia.

|

mm

|

Ø160

|

Ø160

|

|

Hydraulic chuck

Dia.

|

inch

|

|

|

|

Feed

|

|

|

|

|

X/Z axis rapid

feed

|

m/min

|

16/12

|

16/12

|

|

X/Z axis servo motor

power

|

kW

|

3.1/3.1

|

4/4

|

|

Turret

|

|

|

|

|

Tool post stations

|

pcs

|

12

|

12

|

|

Outside Dia. Cuting tool

shank

|

mm

|

32×32

|

25×25

|

|

Max.inner Dia. cutting tool

shank

|

mm

|

Ø50

|

Ø40

|

|

Live tool motor

power

|

kW

|

-

|

3.7/5.5

|

|

Max. speed of Live

tool

|

rpm

|

-

|

4000

|

|

Tailstock

|

|

|

|

|

Tailstock sleeve

Dia.

|

mm

|

Ø100

|

Ø100

|

|

Tailstock sleeve

travel

|

mm

|

200

|

200

|

|

Tailstock sleeve bore

taper

|

|

MT NO.6

|

MT NO.6

|

|

Others

|

|

|

|

|

Bed structure

|

|

45° Slant bed

|

45° Slant bed

|

|

Total power

capacity

|

kVA

|

40

|

38

|

|

Cooling pump power

|

W

|

750

|

750

|

|

Lubrication pump

capacity

|

L

|

1.8

|

1.8

|

|

Overall dimensions (

L×W×H

)

|

mm

|

5600×1900×2150

|

5600×1900×2150

|

|

Net weight

|

kg

|

8000

|

8000

|

|

Precision

|

mm

|

IT5~6

|

IT5~6

|

|

Radial runout of spindle taper

hole

|

mm

|

≤0.003

|

≤0.003

|

|

X-axis positioning

accuracy

|

mm

|

≦0.008

|

≦0.008

|

|

Z axis positioning

accuracy

|

mm

|

≦0.016

|

≦0.016

|

|

X-axis repeat positioning

accuracy

|

mm

|

≦0.005

|

≦0.005

|

|

Z-axis repeat positioning

accuracy

|

mm

|

≦0.010

|

≦0.010

|

|

Processing workpiece

roundness

|

mm

|

≤0.005/Ø120

|

≤0.005/Ø120

|

|

Processing workpiece

cylindricity

|

mm

|

≤0.010/Ø120×150

|

≤0.010/Ø120×150

|

|

Processing workpiece

flatness

|

mm

|

≤0.02/Ø500

|

≤0.02/Ø500

|

|

Processing workpiece surface

roughness

|

|

≤Ra1.25

|

≤Ra1.25

|

2, Standard Configuration:

- FANUC 0i MF (5) plus CNC controller+FANUC X/Z axis servo motor+ FANUC

15/18.5kW big range spindle motor( about 220Nm)

- A2-8 spindle (spindle bore 80mm for Max. dia.65mm bar)

- Box guides

- Taiwan 12” HOLLOWED hydraulic 3-jaw chuck +Taiwan hollowed oil

cylinder

- Taiwan 12-way hydraulic turret (includes Square tool holder x 3

pcs+Boring tool holder x 3 pcs)

- Hydraulic tailstock

- Hydraulic station+Hydraulic control pedals

- Lubrication and coolant system

- Air conditioner for electrical cabinet

- Auto chip conveyor system

- LED working lamp

- CE safety lock +Tricolor alarm light+Door lock switch

- Lubrication and coolant system

- SIMENS or Schneider main electrical components

- Maintenance tool box with tools

- English operation manuals

- Test report of accuracy inspect

- Export wooden pallets with IPPC stamps

3

, Optional with Extra

Costs

:

(

E

very option maybe make

the specifications differences, need to check finally).

|

No.

|

Description

|

Price

|

Remark

|

|

1

|

With GSK CNC controller+ GSK

servo motors for X/Z/spindle

|

|

|

|

2

|

FANUC 0i TF (1) CNC controller +FANUC α22 servo motors for X/Z axis + spindle motor 18.5/22kw

|

|

|

|

3

|

With Siemens 828D CNC controller+Siemens main motors+Siemens shop turn

functions

|

|

|

|

4

|

With German ZF gear box (1:4 transmission ratio)

|

|

|

|

5

|

Manual guide 0i for FANUC (5) CNC controller

|

|

|

|

6

|

Manual guide i for FANUC (1) CNC controller

|

|

|

|

7

|

Soft jaws for 12” 3-jaw hydraulic chuck

|

|

|

|

8

|

Hard jaws for 12” 3-jaw hydraulic chuck

|

|

|

|

9

|

Square/boring tool holder for hydraulic turret

|

|

|

|

10

|

Renishaw tool probe system HPMA

|

|

|

|

11

|

Bar feeding system LNS DH65L dia.5-65x 1200mm

|

|

|

|

12

|

Bar feeding system LNS DH65L dia. 5-65x 1500mm

|

|

|

|

13

|

Taiwan hydraulic steady rest (30-245mm)

|

|

|

|

14

|

Programmable tailstock for 1000mm

|

|

|

|

15

|

Improve to A2-11

spindle (1500rpm) with bigger

12” hollow hydraulic chuck +hollow oil

cylinder (130mm spindle bore

Dia. 110mm bar capacity

)

|

|

|

|

16

|

Improve to A2-11

spindle (1500rpm) with 15” hollow hydraulic chuck +hollow oil cylinder

(

130mm spindle bore

Dia. 110mm bar capacity

)

|

|

|

4, Commercial Terms:

l Delivery: around 60-75 working days after order deposit as standard configurations.

l Quotation validity : 2 months in your country;

l Payment: 30% T/T in advance, 70% T/T before shipment.

l Warranty: The warranty period is general 13 months after B/L date. During the warranty period, we will provide free replacement parts (EXW---not included air freight) which are easy worn-out. And also parts caused by machine itself quality problems. Meanwhile, the machine should be under normal operation according to Operation Manual.(Except for improper operation or man-made damaged by buyers).

Special note: specifications, color, configurations are different from orders to orders.

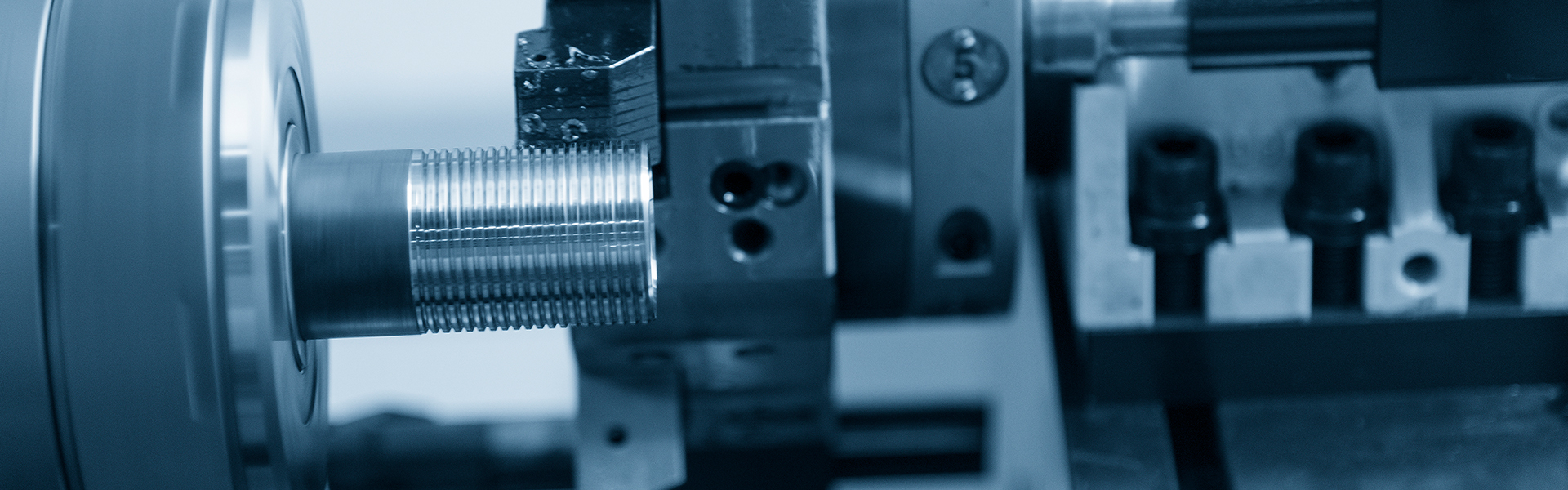

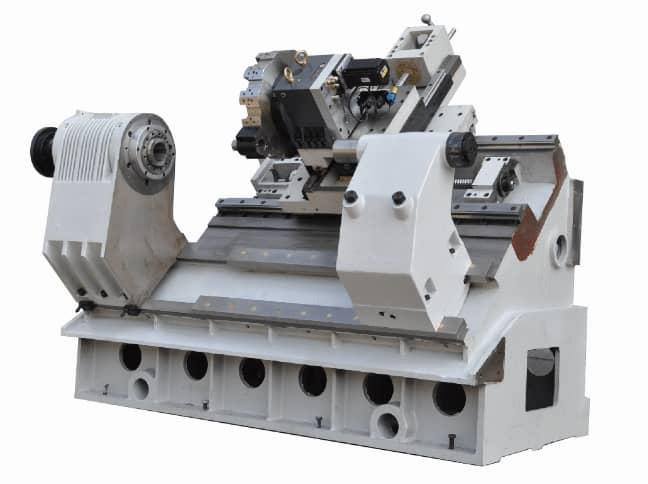

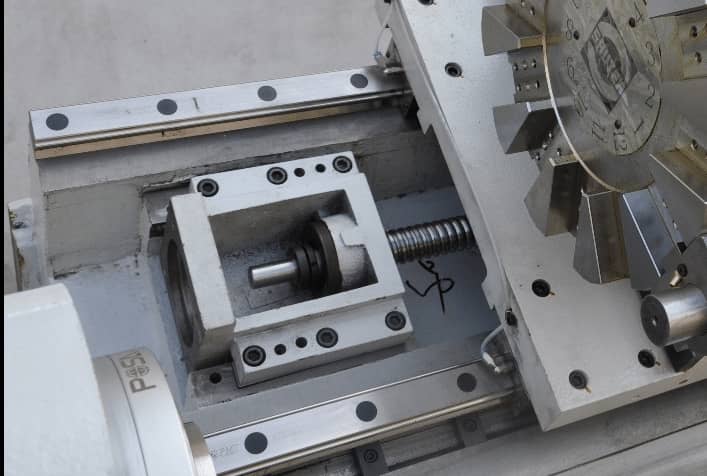

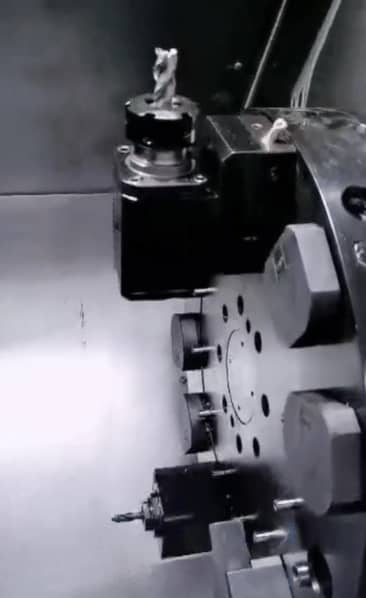

5, More Machine Pictures:

|

|

|

|

|

|

|

|

|

|

|

|