Description

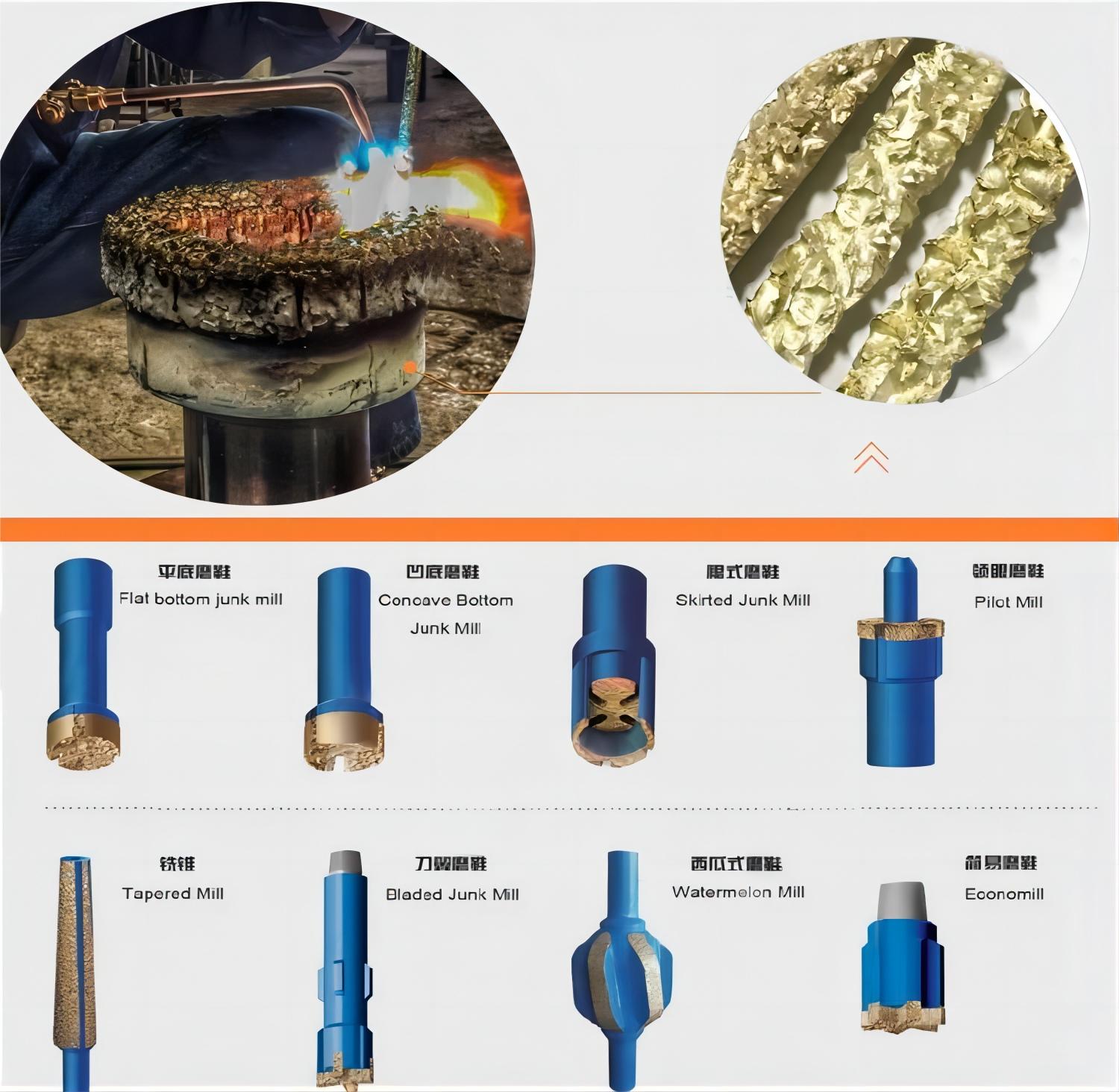

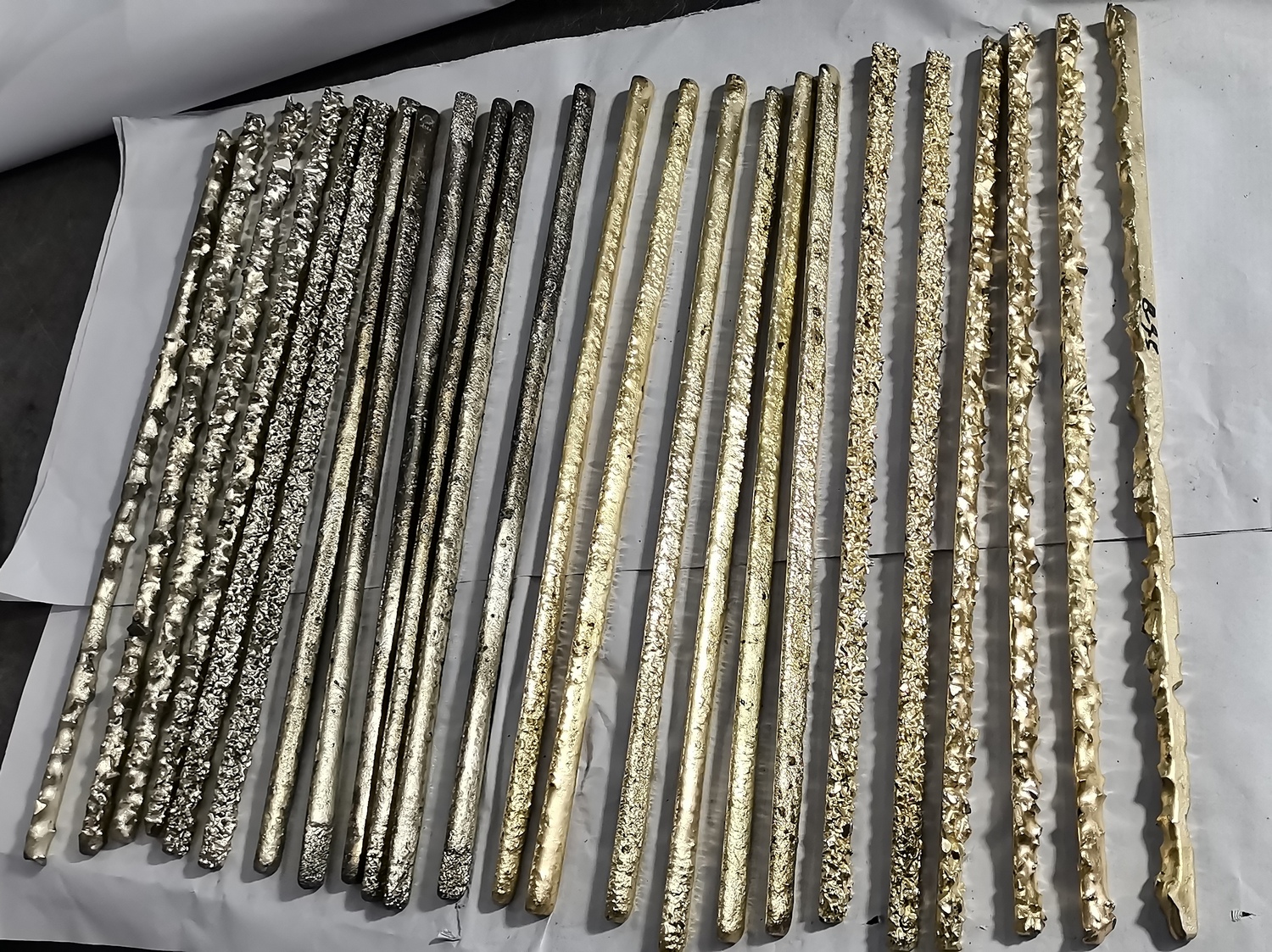

The tungsten carbide welding rod is made up of tungsten carbide grits (WC and Co) welded together by welding flux which consists of bronze(Cu) and nickel. Under high temperature it can melt upon surfaces of different tools. Once cooled down, it will become a wear layer, serving as wear-resistance or cutting purposes.

Composition: WC and Co

Hardness: HRA 89~91

Grade | Size | Grit Size (mm) | Color |

YD-9.5 | 9.5 | 9.5~6.5 | dark green |

YD-8 | 8.0 | 8.0~6.5 | dark blue |

YD-6.5 | 6.5 | 6.5~5.0 | red |

YD-5 | 5.0 | 5.0~3.0 | yellow |

YD-3 | 3.0 | 3.0~2.0 | pink |

YD-10 mesh | 10 mesh | 10~18 mesh | light green |

YD-18 mesh | 18 mesh | 18~30 mesh | light green |

YD-30 mesh | 30 mesh | 30-50 mesh | light yellow |

Application

The tungsten carbide welding rod is mainly used for anti-wearing and cutting tools in the oil, mining, coal mining, geology, construction and other industries, such as: milling shoes, grinding, centralizer, reamer, drill pipe joints, hydraulic cutter, scraper, plough planer knives, core bit, piling drill, twist drill, etc..