I. Introduction to the Functions of the VDM Series Beveling Machine:

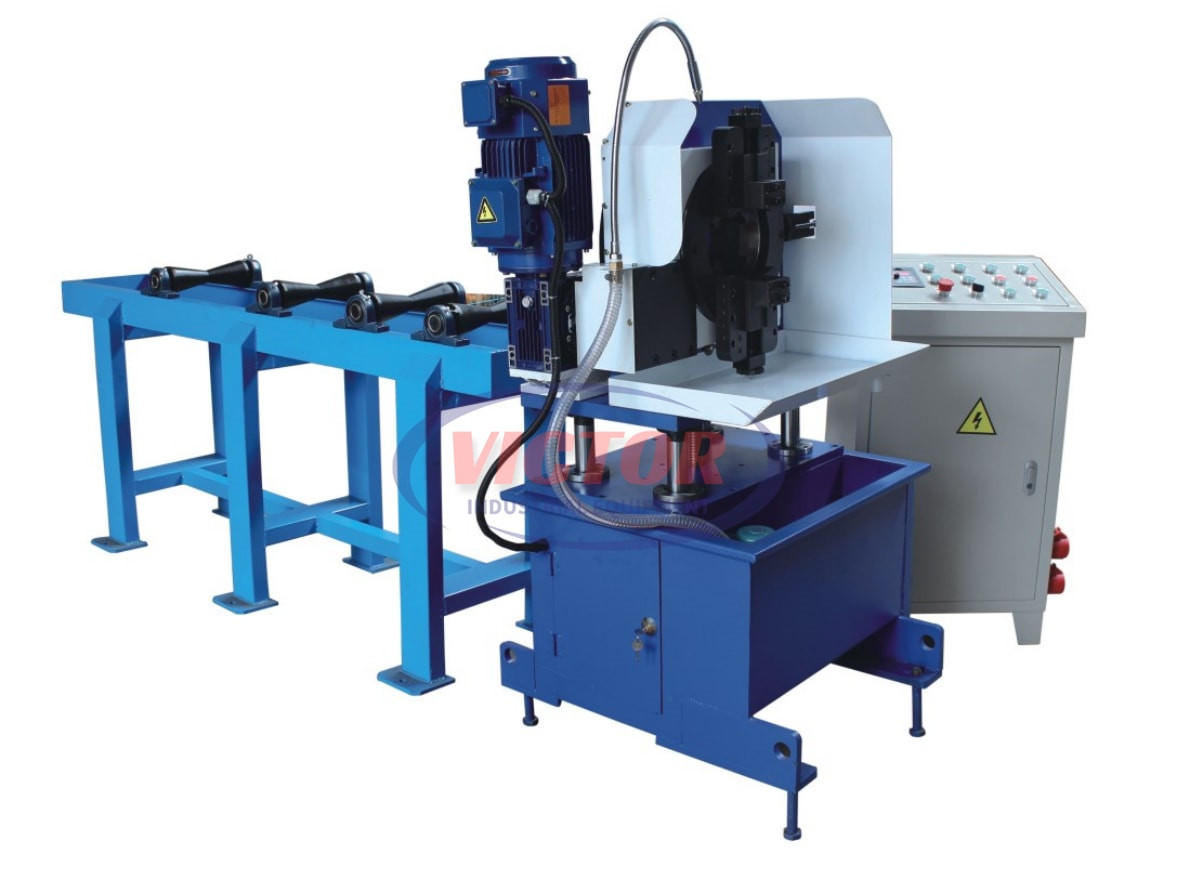

The VDM series high-speed cutting and beveling all-in-one machine is equipped with a 380V variable frequency motor, user-friendly control panel, and a stable tool feed mechanism. The tool rotates several times around the pipe, enabling it to cut the pipe efficiently. This series boasts large cutting capacity, high cutting efficiency, smooth and burr-free cuts without deformation, and can perform both cutting and beveling tasks. By changing the tools, it can achieve bevel cuts at different angles and can handle both pipe end beveling and middle section beveling.

II. Features of the VDM Series Beveling Machine:

It's designed for standard beveling of pipe ends but can also be used for cutting and beveling at the middle of the pipe.

After cutting, it's ready for direct welding with no burrs or deformation.

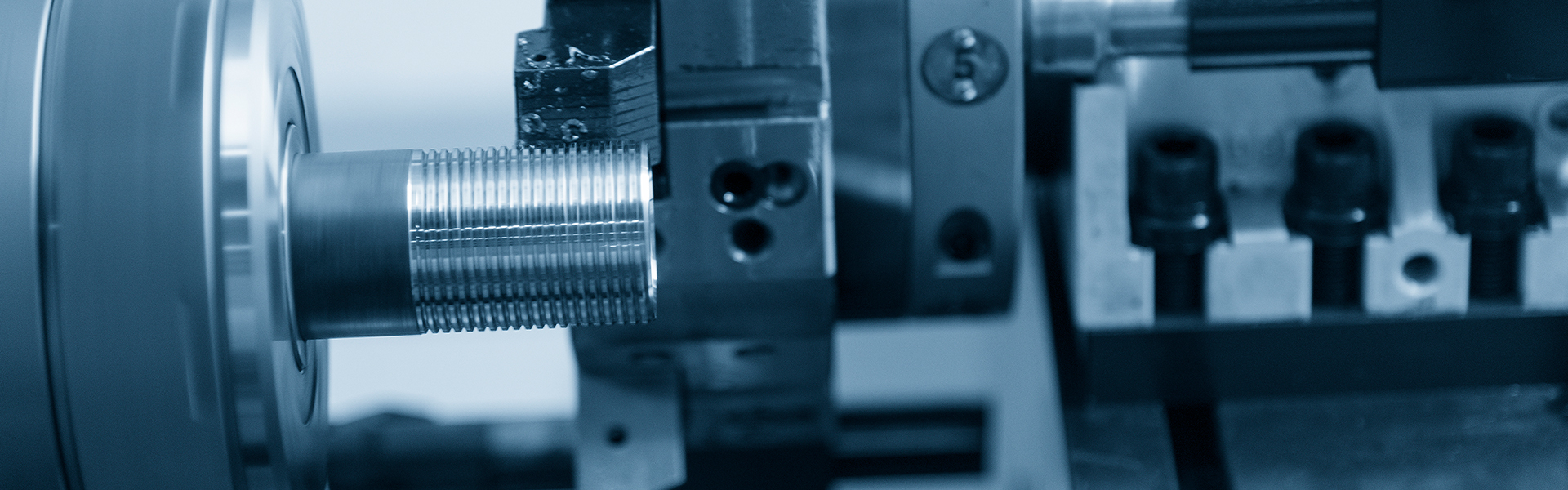

Rotating cold cutting method, where the rotating blade cuts along the pipe's exterior, ensures a vertical cut end face.

Can process any type of pipe material, including carbon steel, stainless steel, alloy steel, etc.

Multi-point circumferential clamping effectively prevents pipe deformation during clamping.

When used with a feeding platform, the main machine can be adjusted in height to accommodate different pipe diameters.

Its compact design takes up minimal space, is easy to transport, and is suitable for both fixed workshop use and on-site applications.

Features a quick-change clamping module and a variable speed motor for high efficiency and energy-saving.

The CNC cutting beveling machine from the VDM series uses a dual-side multi-claw automatic centering clamp. The rotation bearing mode and tool-rotating feed, combined with the automatic tool feeding mechanism, allow for rapid beveling and cutting of pipes.

It eliminates the cumbersome steps some clients had of first using a band saw for cutting, then beveling.

III. Configuration List:

Pipe Cutting and Beveling Machine VDM-168 Packing List:

1. Pipe Cutting and Beveling Machine VDM-168 1 Set VDM-426 1 Set

2. Hexagonal (Allen) wrench - 1 Set -

3. Tool pad block - 1 Piece -

4. Tool pad blade - 5-7 Pieces -

5. Extended clamping block - 6 Pieces -

6. Extended tool holder - 2 Pieces

7. Electric box key - 1 Set

8. Cutting blade - 1 Piece

9. Beveling blade - 1 Piece

10. Packaging 1 Unit -

11. Transportation 1 Unit -

12. Installation, Calibration, Acceptance 1 Unit -

IV. Technical Parameters of the CNC Pipe Beveling Machine

1. The pipe cutting and beveling machine offers high precision, rigidity, efficiency, automation, and reliability. It has been extensively applied in fields such as petroleum, petrochemical, chemical, power, shipbuilding, and marine engineering.

2. Technical Standards

GB50231 General Code for Construction and Acceptance of Mechanical Equipment Installation Engineering

GB4064 Safety Design Guidelines for Electrical Equipment

GB 5226.1 Safety of Machinery - Electrical Equipment of Machines

GB15760 General Technical Conditions for Safety Protection of Metal Cutting Machine Tools

GB/T2349 Series of Cylinder Piston Strokes in Hydraulic and Pneumatic Systems and Components

ASTM B31.3 Standard for Manufacturing of Process Piping

3. Suitable Operating Environment

Power Supply Requirements: 380V 50Hz

Altitude: Below 1000m

Ambient Temperature: -5℃ to +60℃ for normal operation.

Relative Humidity:

Maximum monthly average relative humidity: 80%.

Maximum daily average relative humidity: 85%.

4.

VDM-168 Main Technical Specifications:

1) Applicable pipe diameter: Ø22-Ø168mm

2) Applicable wall thickness: 2-30mm

3) Bevel type: V-shaped

4) Applicable materials: Carbon steel pipe, alloy steel pipe, stainless steel pipe, etc.

5) Technical Specifications:

Cooling system: High-performance circulating spray water

Feed mode: Automatic feeding

Retraction mode: Manual retraction

Clamping method: Electric clamping with torque protector

Main motor power: 2.2kw

Cutting speed: 0-40rpm frequency control

Mainframe elevation method: Electric lifting

Lifting motor power: 1.1kw

Lifting protection: Lifting limit

Cutting amount: 0.07mm/r

Control system: Integrated control system with emergency stop button on the panel

Protective function: The cutting disc is equipped with a protective cover

VDM-426 Main Technical Specifications:

1) Applicable pipe diameter: Ø219-Ø426mm

2) Applicable wall thickness: 3-30mm

3) Bevel type: V-shaped

4) Applicable materials: Carbon steel pipe, alloy steel pipe, stainless steel pipe, etc.

5) Technical Specifications:

Cooling system: High-performance circulating spray water

Feed mode: Automatic feeding

Retraction mode: Manual retraction

Clamping method: Eight-claw self-centering hydraulic clamping.

Hydraulic pump displacement: 6ML/r

System rated pressure: 16MPa

Working pressure: 5MPa

Hydraulic system motor power: 2.2kw

Oil tank capacity: 60L

Hydraulic system cooling method: Air cooler

Main motor power: 5.0kw

Cutting speed: 0-26rpm with frequency control

Mainframe elevation method: Electric lifting

Lifting motor power: 1.5kw

Lifting protection: Lifting limit

Cutting amount: 0.07mm/r

Control system: Integrated control system with emergency stop button on the panel

Protective function: The cutting disc is equipped with a protective cover

V. Conveyor Roller for Pipes Description:

This machine requires corresponding rollers for processing pipes. The rollers can be at a fixed height, and the machine can adjust its center to align with the rack height. The rack length can be customized based on the pipe length, and it is recommended to use V-type rollers for the roller conveyor.

VI. Basic Equipment Manufacturing Standards

1. In-built air switches, electrical components that meet the national 3C certification, and other measures ensure production safety in line with national safety production standards.

2. Electrical equipment protection rating ≥ IP23.

3. Core electrical components are sourced from renowned domestic and international brands.

4. Each set of equipment is equipped with ground protection device.

5. Internal wiring of the equipment uses conduit method, while external wiring uses a cable tray method, effectively protecting the cables from damage and preventing electrical leakage.

6. The mechanical parts are designed according to heavy-duty structures, ensuring adequate bearing strength.

7. All moving parts of the equipment are equipped with safety protection, anti-collision protection devices, and limit switches.