1, General Introduction

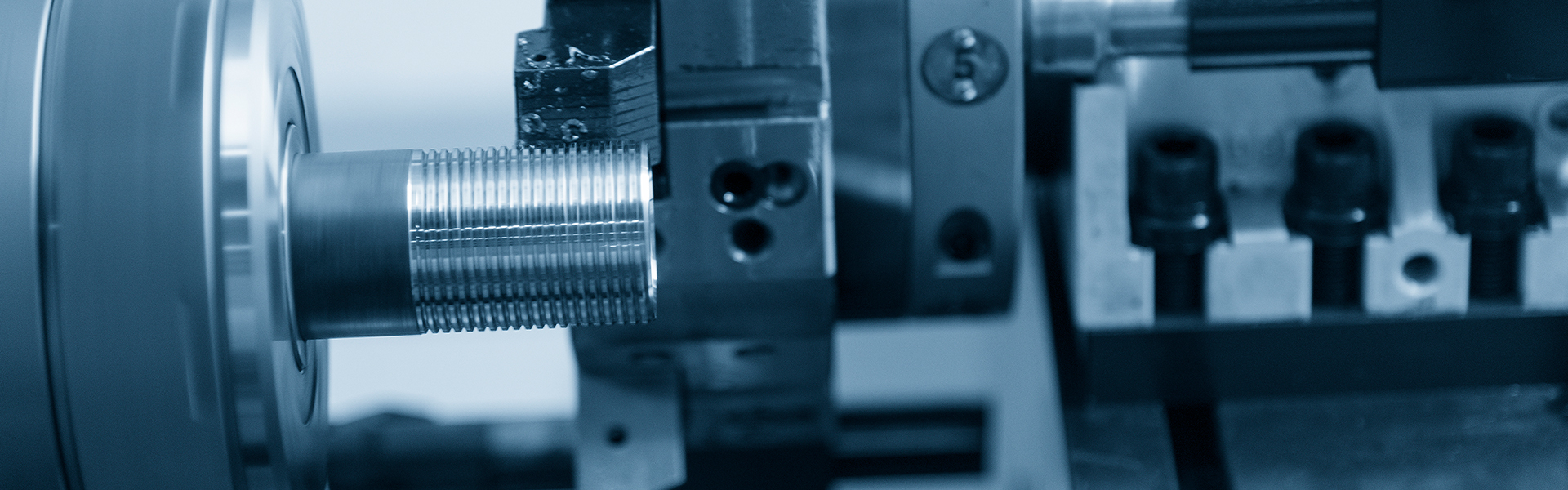

WKD-M1200C CNC specialized cylindrical grinding machine is used to grind the cylinder outside surface of various types of medium-size parts.

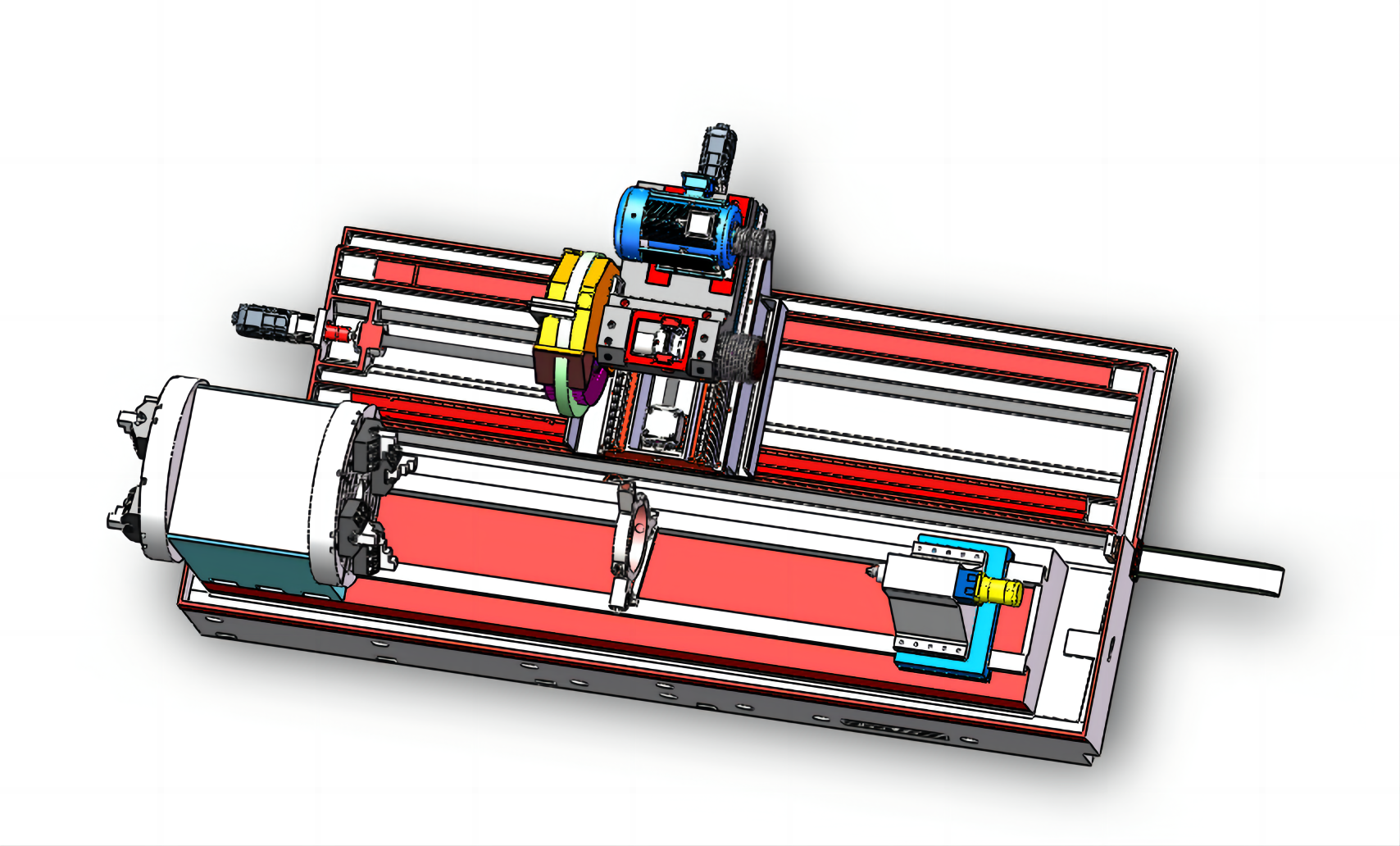

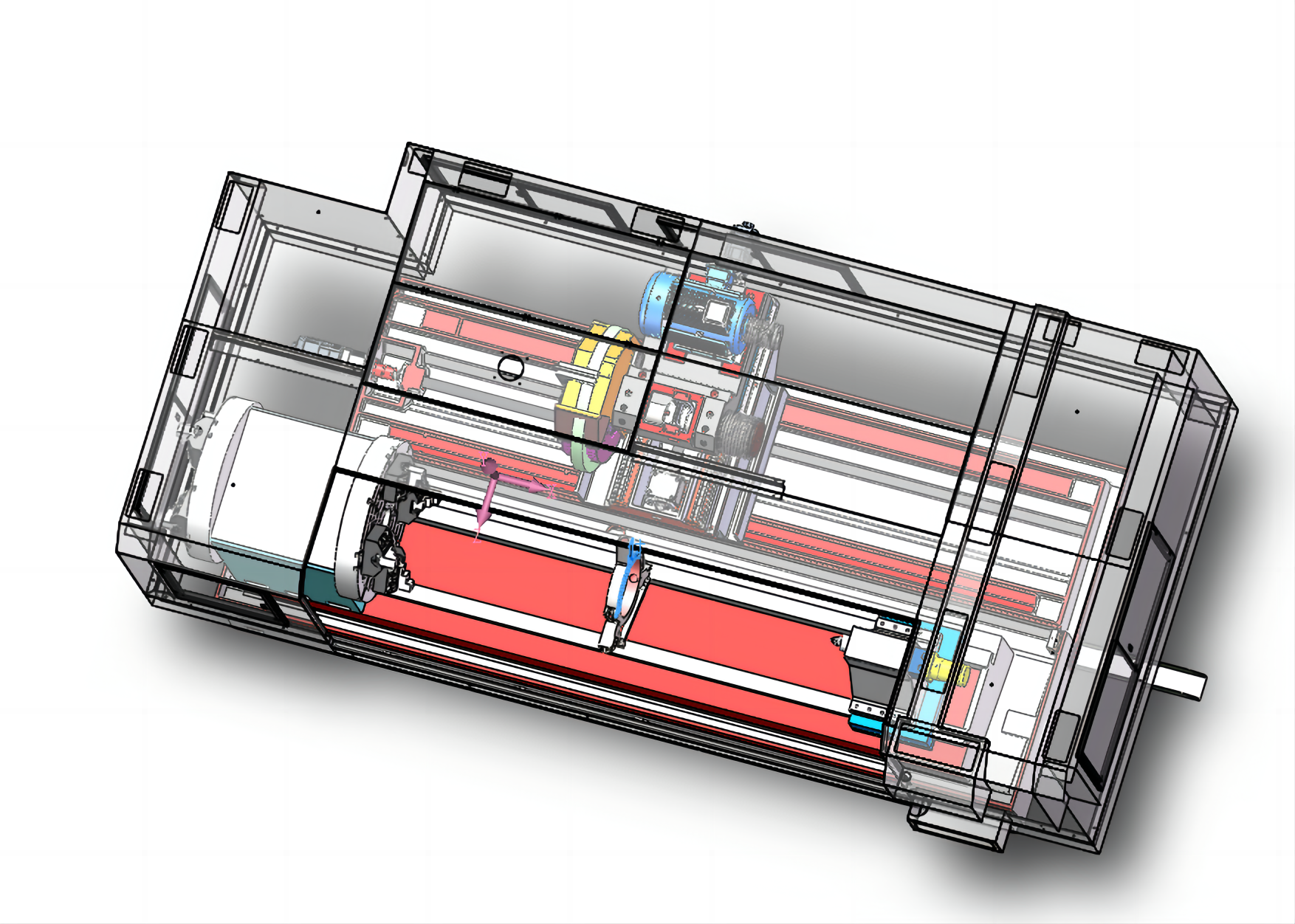

The machine adopts the cylindrical/internal grinding machine CNC system of GSK CNC Equipment Co. Ltd. (GSK). Radial cutting (X axis) and axial reciprocating motion (Z axis) is controlled by servo system. The grinding wheel, workpiece rotation, oil pump, cooling pump are separately driven by independent motors.

The machine adopts the structure of integral bed and moving grinding carriage. The workpiece is rotating on the lathe bed, and the grinding carriage is moving lengthwise back and forth, and feeding crosswise at the same time.

The grinding carriage is driven by servo motor to move lengthwise (Z axis) and crosswise (X axis). The servo motor has the advantages of swift response, high accuracy, fast acceleration and deceleration, etc.. The servo motor drives ball screws and makes the carriage bed to move back and forth rapidly in the direction of X axis and Z axis, thus creating the feeding of the grinding carriage.

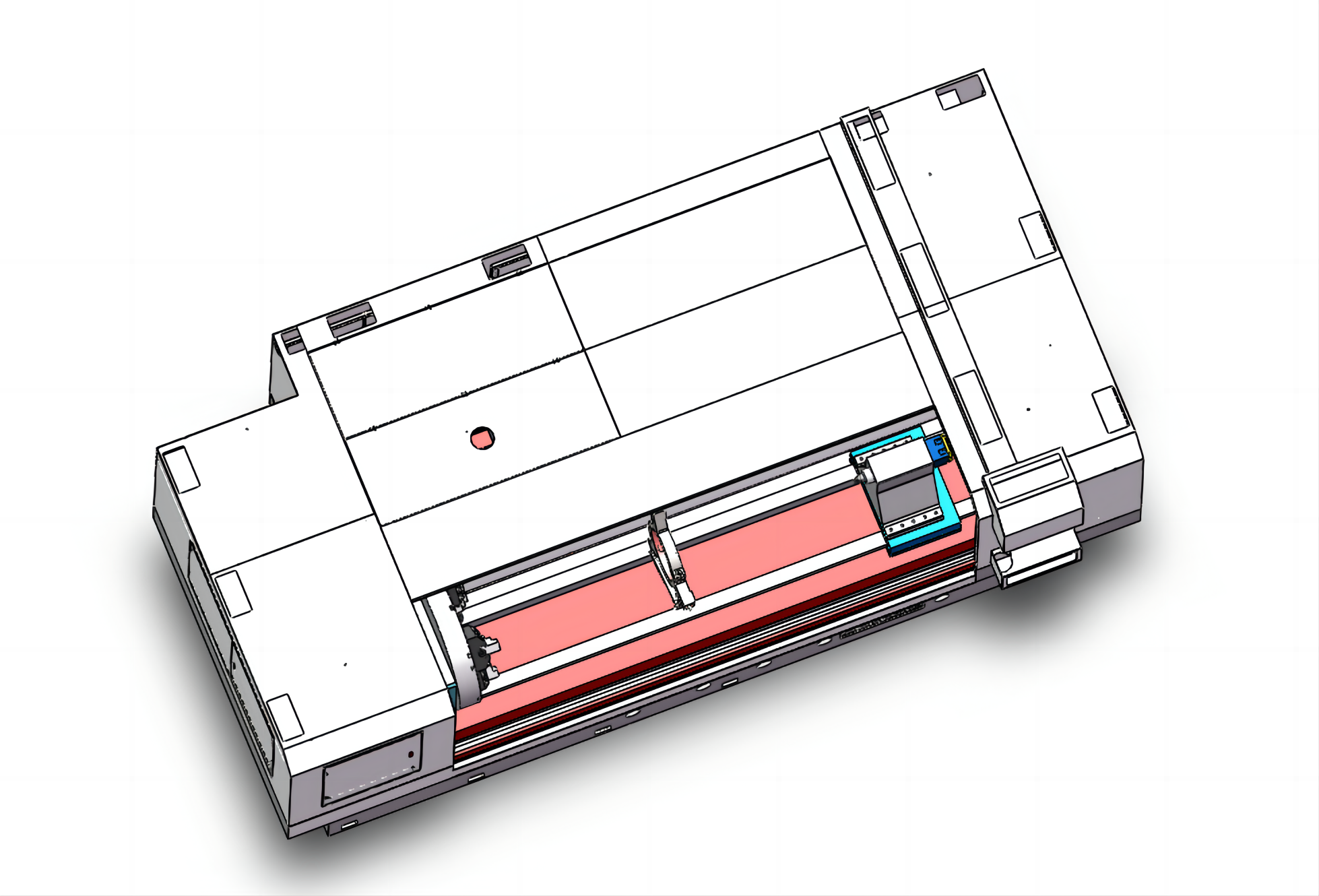

The bed ways at the two ends of the lathe table are equipped with retractable shield. The guideways at the two ends of the carriage bed are equipped with retractable shield. The machine is equipped with reliable security interlocking protection function in the mechanical area, electrical area and hydraulic area, etc.

2, Technical Parameters

● Main Parameters

Maximum Grinding Diameter φ1,200mm

Maximum Grinding Length 3,000mm

Maximum Workpiece Holding Length 3,100mm

Center Height 650mm

Maximum Workpiece Weight 3,000KG

4-jaw Chuck ID 14” (35cm)

● Grinding Carriage

Grinding Wheel Size φ750x75xφ305mm

Grinding Wheel Linear Speed < 35meter/sec

Maximum Travel (X Axis) 3,000mm

Maximum Travel (Z Axis) 500mm

● Headstock

Spindle Center Plate Rotation Speed 10-100round/min

● Tailstock

Maximum Travel (Manual) 1,500mm

● Cooling System

Flow Rate of Cooling Pump 50L/min

● Motor Power

Grinding Carriage Motor Power 18.5 kw

Headstock Motor Power 15kw

Oil Pump Motor Power 0.75kw

Cooling Pump Motor Power 0.125kw

● Machine Dimensions(L*W*H): 6,500*2,600*2,300mm

● Estimated Weight: 20 tons

3, Operating Conditions and Manufacturing Standards

1) Operating Conditions

Power Supply:3-phase AC, 380V±10% ,50HZ±1%

Electrical System :Three-phase Four-wire System

Working Environment Temperature:0º~40ºC

Working Environment Humidity:≤90%

2) Manufacturing Standards

JB/T7418.2-2007: Cylindrical Grinding Machine General Specifications;

GB5226.1-2008: Electrical Safety of Machinery - Electrical Equipment of Machines - Part 1: General Requirements

GB/T9061—2006: General Specifications for Metal-Cutting Machine Tools

JB4029—2000: Specifications of Grinding-wheel Guard for Safety

4, Introduction of Main Components

1) Lathe Bed

The lathe bed is of integral structure, and uses high-strength inoculated cast iron HT250 which undergoes special treatment. It has high overall rigidity and stability, surface wear resistance and shock resistance. It fully meets the requirements of high-efficiency and high-precision equipment, and maintains the technical precision and stability of the equipment during long-time use. We will conduct leakage-check test before assembly.

2) Grinding Carriage and Feeding System

The grinding carriage adopts high-strength inoculated cast iron HT250 which undergoes special treatment. It has high overall rigidity and stability.The spindle system adopts two sets of split sleeve dynamic pressure bearing and is with high precision and good rigidity. We use special technology to maintain the balance and stress correspondence of the two sets of bearing bushes, thus ensure that the spindle of the grinding wheel can keep high rotation accuracy and working stability in the process of long-time grinding.

We also implement high filtration precision measures on the lubrication oil of the spindle grease-box, to control the oil temperature of the spindle system, thus achieve the overall stability of the grinding carriage, and the spindle system will work under the specified technical parameters all the time. The consistent size precision of the workpiece is thus realized. The periodic maintenance and adjustment of the spindle system is convenient and reliable.

In the process of automatic cyclic feeding, the machine will automatically dress the grinding wheel and compensate after dressing. You can set the frequency of dressing the grinding wheel. The feeding of grinding carriage is driven by servo motor.

3) Headstock

The headstock is fixed on the lathe bed.

The structure of the headstock is the same as the horizontal lathe. 4-jaw chuck can be installed on the spindle nose.

4) Tailstock

4-jaw chuck can be installed on the tailstock sleeve nose.

5) Cooling System

The cooling system of the lathe is of independent circulating filtration. It fully meets the requirement of continuous high-efficiency grinding and ensures the grinding quality.

5, Accompanying Technical Documents

1) User manual which includes basis diagrams, electrical schematic diagram, wiring diagram, hydraulic schematic diagram, etc..

2) List of purchased parts and quick-wear parts

3) CNC programming manual

6, List of Main Purchased Parts

Name | Part NO. | Quantity | Brand |

CNC System | GSK986 | 1 | GSK |

Ball Screw | FFZD5010 | 1 | Wuxi SJR |