Drill Collar

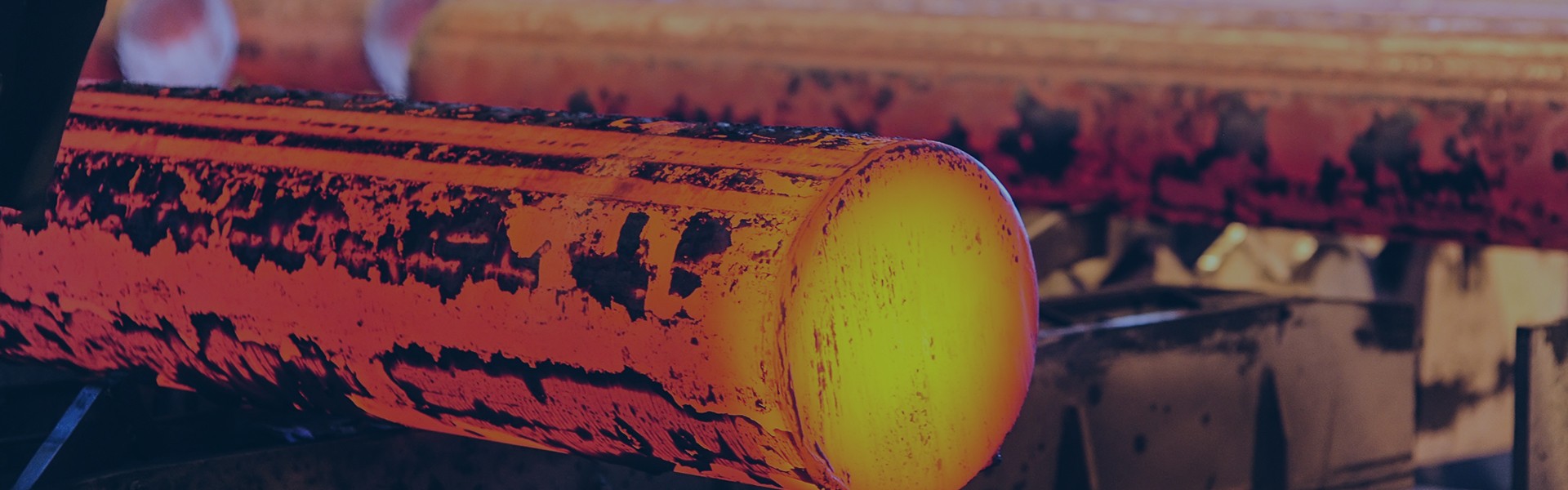

Drill collars are manufactured from a solid bar of modified alloy steel. The solid bars are quenched and tempered to obtain the required mechanical properties, then trepanned, drifted and threaded. Drill collars are furnished as slick or spiraled in 30 or 31 foot lengths. However, both styles accomplish the same task. Spiral groove drill collars were introduced in more recent years and are thought to help prevent the drill string from getting stuck in the hole by allowing drilling debris and lubricant to pass more freely around the drill collar.