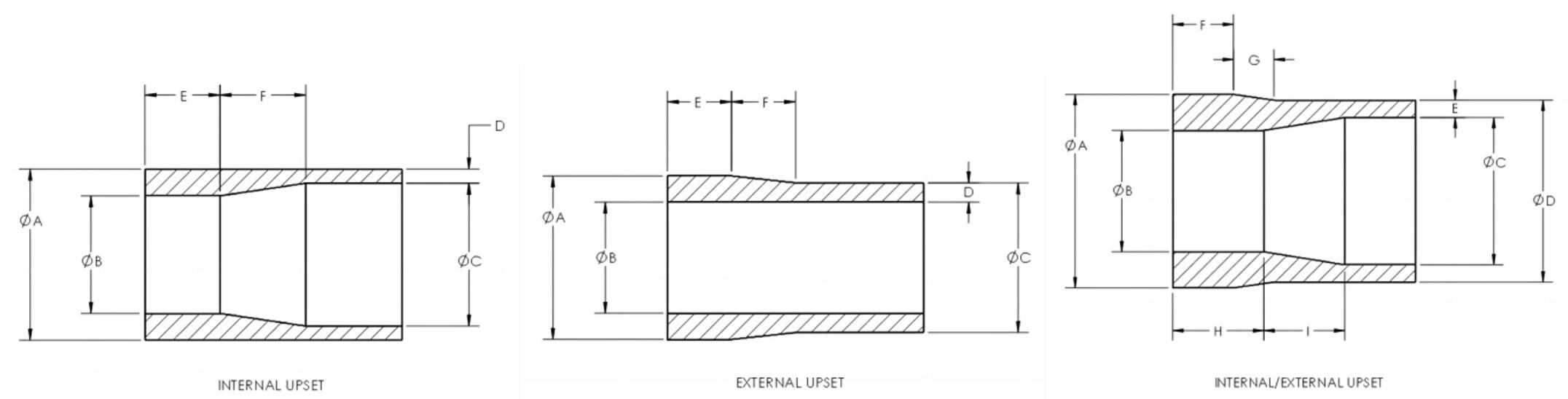

Upset

The upset (thread-end finish) refers to the

wall of the tool joint at the threaded connection. Drill pipe is offered with

an internal upset (IU), an external upset (EU), or an internal-external upset

(IEU).

IU - In an internal upset increased

thickness along the inside walls compensate for the metal removed in threading

with a uniform, straight outside wall.

EU - In an external upset the increased

thickness along the outside diameter of the tubing compensates for the metal

removed in threading with a straight bore.

IEU - In an internal-external upset thickness is increased along both the inside and outside walls of the pipe to compensate for the metal removed in threading.

Size and Weight

|

Pipe |

Tool

Joint |

|||||||||

|

Size

OD, |

Nominal

Weight, |

Upset

Type |

Grade |

Wall

Thickness, |

ID, |

Connection

Type |

OD, |

ID, |

Pin

Tong Space, |

Box

Tong Space, |

|

2-3/8 |

6.65 |

EU |

E-75 |

0.280 |

1.815 |

NC26 |

3-3/8 |

1-3/4 |

7 |

8 |

|

X-95 |

0.280 |

1.815 |

NC26 |

3-3/8 |

1-3/4 |

7 |

8 |

|||

|

G-105 |

0.280 |

1.815 |

NC26 |

3-3/8 |

1-3/4 |

7 |

8 |

|||

|

S-135 |

0.280 |

1.815 |

NC26 |

3-5/8 |

1-3/4 |

7 |

8 |

|||

|

2-7/8 |

10.40 |

EU |

E-75 |

0.362 |

2.151 |

NC31 |

4-1/8 |

2-1/8 |

7 |

9 |

|

X-95 |

0.362 |

2.151 |

NC31 |

4-1/8 |

2 |

7 |

9 |

|||

|

G-105 |

0.362 |

2.151 |

NC31 |

4-1/8 |

2 |

7 |

9 |

|||

|

S-135 |

0.362 |

2.151 |

NC31 |

4-3/8 |

1-5/8 |

7 |

9 |

|||

|

3-1/2 |

13.30 |

EU |

E-75 |

0.368 |

2.764 |

NC38 |

4-3/4 |

2-11/16 |

8 |

10-1/2 |

|

X-95 |

0.368 |

2.764 |

NC38 |

5 |

2-9/16 |

8 |

10-1/2 |

|||

|

G-105 |

0.368 |

2.764 |

NC38 |

5 |

2-7/16 |

8 |

10-1/2 |

|||

|

S-135 |

0.368 |

2.764 |

NC38 |

5 |

2-1/8 |

8 |

10-1/2 |

|||

|

15.50 |

EU |

E-75 |

0.449 |

2.602 |

NC38 |

5 |

2-9/16 |

8 |

10-1/2 |

|

|

X-95 |

0.449 |

2.602 |

NC38 |

5 |

2-7/16 |

8 |

10-1/2 |

|||

|

G-105 |

0.449 |

2.602 |

NC38 |

5 |

2-1/8 |

8 |

10-1/2 |

|||

|

S-135 |

0.449 |

2.602 |

NC40 |

5-1/2 |

2-1/4 |

7 |

10 |

|||

|

4 |

14.00 |

IU |

E-75 |

0.330 |

3.340 |

NC40 |

5-1/4 |

2-13/16 |

7 |

10 |

|

X-95 |

0.330 |

3.340 |

NC40 |

5-1/4 |

2-11/16 |

7 |

10 |

|||

|

G-105 |

0.330 |

3.340 |

NC40 |

5-1/2 |

2-7/16 |

7 |

10 |

|||

|

S-135 |

0.330 |

3.340 |

NC40 |

5-1/2 |

2-7/16 |

7 |

10 |

|||

|

EU |

E-75 |

0.330 |

3.340 |

NC46 |

6 |

3-1/4 |

7 |

10 |

||

|

X-95 |

0.330 |

3.340 |

NC46 |

6 |

3-1/4 |

7 |

10 |

|||

|

G-105 |

0.330 |

3.340 |

NC46 |

6 |

3-1/4 |

7 |

10 |

|||

|

S-135 |

0.330 |

3.340 |

NC46 |

6 |

3 |

7 |

10 |

|||

|

15.70 |

IU |

E-75 |

0.380 |

3.240 |

NC40 |

5-1/4 |

2-11/16 |

7 |

10 |

|

|

X-95 |

0.380 |

3.240 |

NC40 |

5-1/4 |

2-7/16 |

7 |

10 |

|||

|

G-105 |

0.380 |

3.240 |

NC40 |

5-1/2 |

2-7/16 |

7 |

10 |

|||

|

S-135 |

0.380 |

3.240 |

NC40 |

5-1/2 |

2 |

7 |

10 |

|||

|

EU |

E-75 |

0.380 |

3.240 |

NC46 |

6 |

3-1/4 |

7 |

10 |

||

|

X-95 |

0.380 |

3.240 |

NC46 |

6 |

3-1/4 |

7 |

10 |

|||

|

G-105 |

0.380 |

3.240 |

NC46 |

6 |

3-1/4 |

7 |

10 |

|||

|

S-135 |

0.380 |

3.240 |

NC46 |

6 |

3 |

7 |

10 |

|||

|

4-1/2 |

16.60 |

IEU |

E-75 |

0.337 |

3.826 |

NC46 |

6-1/4 |

3 |

7 |

10 |

|

X-95 |

0.337 |

3.826 |

NC46 |

6-1/4 |

3-1/4 |

7 |

10 |

|||

|

G-105 |

0.337 |

3.826 |

NC46 |

6-1/4 |

3 |

7 |

10 |

|||

|

S-135 |

0.337 |

3.826 |

NC46 |

6-1/4 |

2-3/4 |

7 |

10 |

|||

|

EU |

E-75 |

0.337 |

3.826 |

NC50 |

6-5/8 |

3-3/4 |

7 |

10 |

||

|

X-95 |

0.337 |

3.826 |

NC50 |

6-5/8 |

3-3/4 |

7 |

10 |

|||

|

G-105 |

0.337 |

3.826 |

NC50 |

6-5/8 |

3-3/4 |

7 |

10 |

|||

|

S-135 |

0.337 |

3.826 |

NC50 |

6-5/8 |

3-1/2 |

7 |

10 |

|||

|

20.00 |

IEU |

E-75 |

0.430 |

3.640 |

NC46 |

6-1/4 |

3 |

7 |

10 |

|

|

X-95 |

0.430 |

3.640 |

NC46 |

6-1/4 |

2-3/4 |

7 |

10 |

|||

|

G-105 |

0.430 |

3.640 |

NC46 |

6-1/4 |

2-1/2 |

7 |

10 |

|||

|

S-135 |

0.430 |

3.640 |

NC46 |

6-1/4 |

2-1/4 |

7 |

10 |

|||

|

EU |

E-75 |

0.430 |

3.640 |

NC50 |

6-5/8 |

3-5/8 |

7 |

10 |

||

|

X-95 |

0.430 |

3.640 |

NC50 |

6-5/8 |

3-1/2 |

7 |

10 |

|||

|

G-105 |

0.430 |

3.640 |

NC50 |

6-5/8 |

3-1/2 |

7 |

10 |

|||

|

S-135 |

0.430 |

3.640 |

NC50 |

6-5/8 |

3 |

7 |

10 |

|||

|

5 |

19.50 |

IEU |

E-75 |

0.362 |

4.276 |

NC50 |

6-5/8 |

3-3/4 |

7 |

10 |

|

X-95 |

0.362 |

4.276 |

NC50 |

6-5/8 |

3-1/2 |

7 |

10 |

|||

|

G-105 |

0.362 |

4.276 |

NC50 |

6-5/8 |

3-1/4 |

7 |

10 |

|||

|

S-135 |

0.362 |

4.276 |

NC50 |

6-5/8 |

2-3/4 |

7 |

10 |

|||

|

E-75 |

0.362 |

4.276 |

5-1/2

FH |

7 |

3-3/4 |

8 |

10 |

|||

|

X-95 |

0.362 |

4.276 |

5-1/2

FH |

7 |

3-3/4 |

8 |

10 |

|||

|

G-105 |

0.362 |

4.276 |

5-1/2

FH |

7 |

3-3/4 |

8 |

10 |

|||

|

S-135 |

0.362 |

4.276 |

5-1/2

FH |

7-1/4 |

3-1/2 |

8 |

10 |

|||

|

25.60 |

IEU |

E-75 |

0.500 |

4.000 |

NC50 |

6-5/8 |

3-1/2 |

7 |

10 |

|

|

X-95 |

0.500 |

4.000 |

NC50 |

6-5/8 |

3 |

7 |

10 |

|||

|

G-105 |

0.500 |

4.000 |

NC50 |

6-5/8 |

2-3/4 |

7 |

10 |

|||

|

S-135 |

0.500 |

4.000 |

NC50 |

6-5/8 |

2-3/4 |

7 |

10 |

|||

|

E-75 |

0.500 |

4.000 |

5-1/2

FH |

7 |

3-1/2 |

8 |

10 |

|||

|

X-95 |

0.500 |

4.000 |

5-1/2

FH |

7 |

3-1/2 |

8 |

10 |

|||

|

G-105 |

0.500 |

4.000 |

5-1/2

FH |

7-1/4 |

3-1/2 |

8 |

10 |

|||

|

S-135 |

0.500 |

4.000 |

5-1/2

FH |

7-1/4 |

3-1/4 |

8 |

10 |

|||

|

5-1/2 |

21.90 |

IEU |

E-75 |

0.361 |

4.778 |

5-1/2

FH |

7 |

4 |

8 |

10 |

|

X-95 |

0.361 |

4.778 |

5-1/2

FH |

7 |

3-3/4 |

8 |

10 |

|||

|

G-105 |

0.361 |

4.778 |

5-1/2

FH |

7-1/4 |

3-1/2 |

8 |

10 |

|||

|

S-135 |

0.361 |

4.778 |

5-1/2

FH |

7-1/2 |

3 |

8 |

10 |

|||

|

24.70 |

IEU |

E-75 |

0.415 |

4.670 |

5-1/2

FH |

7 |

4 |

8 |

10 |

|

|

X-95 |

0.415 |

4.670 |

5-1/2

FH |

7-1/4 |

3-1/2 |

8 |

10 |

|||

|

G-105 |

0.415 |

4.670 |

5-1/2

FH |

7-1/4 |

3-1/2 |

8 |

10 |

|||

|

S-135 |

0.415 |

4.670 |

5-1/2

FH |

7-1/2 |

3 |

8 |

10 |

|||

|

6-5/8 |

25.20 |

IEU |

E-75 |

0.330 |

5.965 |

6-5/8

FH |

8 |

5 |

8 |

11 |

|

X-95 |

0.330 |

5.965 |

6-5/8

FH |

8 |

5 |

8 |

11 |

|||

|

G-105 |

0.330 |

5.965 |

6-5/8

FH |

8-1/4 |

4-3/4 |

8 |

11 |

|||

|

S-135 |

0.330 |

5.965 |

6-5/8

FH |

8-1/2 |

4-1/4 |

8 |

11 |

|||

|

27.70 |

IEU |

E-75 |

0.362 |

5.901 |

6-5/8

FH |

8 |

5 |

8 |

11 |

|

|

X-95 |

0.362 |

5.901 |

6-5/8

FH |

8-1/4 |

4-3/4 |

8 |

11 |

|||

|

G-105 |

0.362 |

5.901 |

6-5/8

FH |

8-1/4 |

4-3/4 |

8 |

11 |

|||

|

S-135 |

0.362 |

5.901 |

6-5/8

FH |

8-1/2 |

4-1/4 |

8 |

11 |

|||