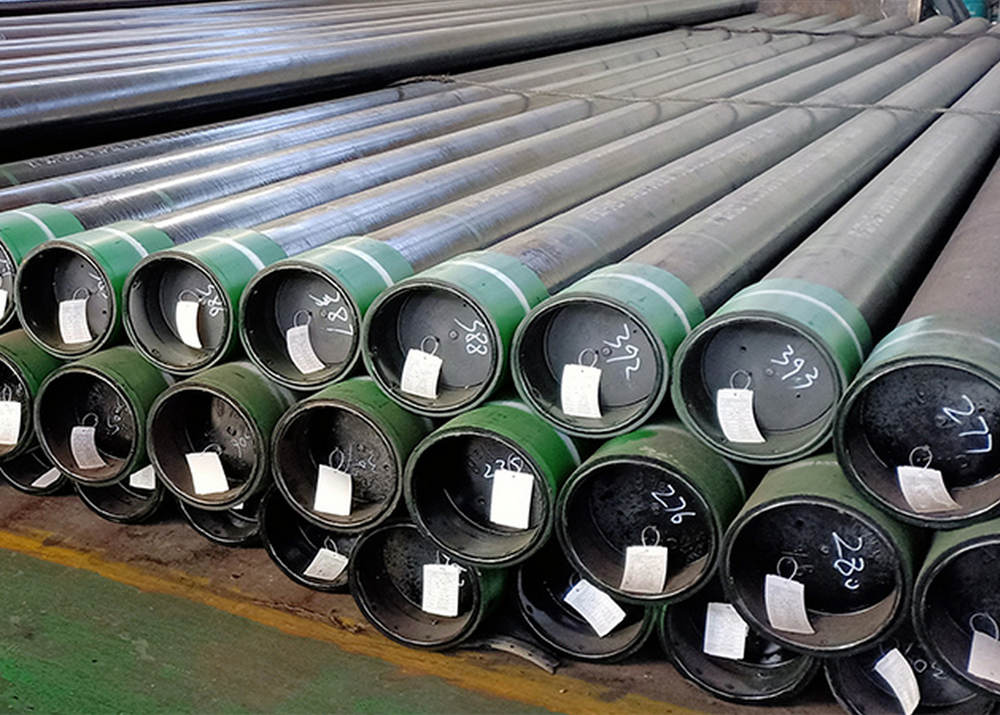

API Casing & Tubing Pipes

General Description

API 5CT casing pipe is used to support the oil and gas pipe wall, and to ensure the drilling process and the post-completion well’s normal operation. Depending on the depth of drilling and geological conditions, each well will use several layers of casing. Unlike tubing and drill pipe, after cementing casing pipes can not be reused, a one-time consumable materials. Therefore, the casing consumption accounts for over 70% of all the oil well pipes. According to usage, it can be divided into the sleeve pipe, surface casing, casing and production casing.

OCTG tubing pipe goes inside the casing pipe because it is the pipe through which oil makes its way out. Tubing is the simplest part of OCTG and it is normally found in the length of 30 ft (9 m), with threaded connection at both ends. The pipe is either used to transport natural gas or crude oil from the producing formation to the facilities where it will be processed after drilling is complete.