Maximum Torque For Maximum Performance

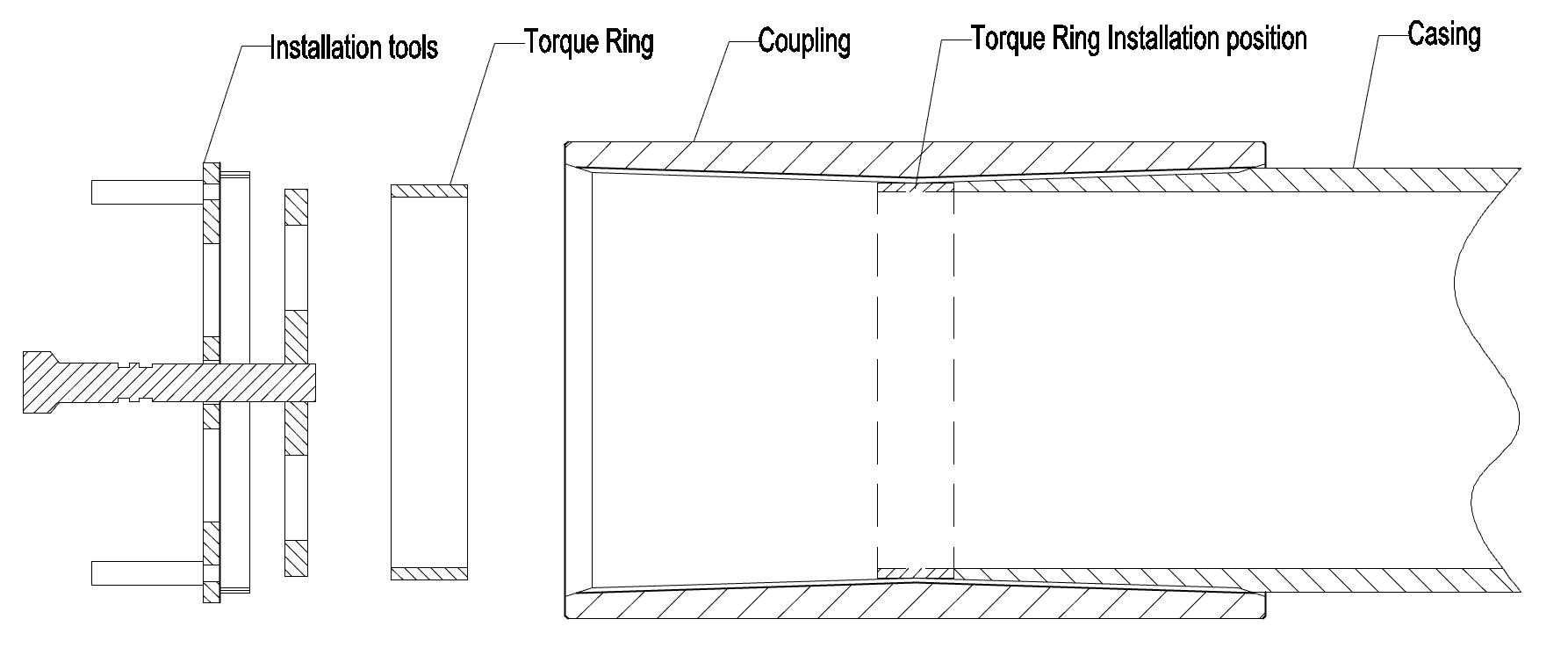

The WKD Torque Rings are an innovative, patented technology that provides premium connection performance at a significantly reduced cost. By creating a positive shouldered makeup identical to a premium connection, API certified pipe can be run at a significantly greater torque value without the risk of thread damage.

Standard API Machine Threading

Ring OD features buttress or LTC threading allowing the ring to internally lock in the proper location of the collar.

API Quality Materials

Torque rings are available in variety of sizes and are composed of the highest grade of steel to match your casing specifications.

Simple Ground Installation

Simple tools can be used to hammer the torque ring in place quickly. Whether the installation is correct is judged according to the scale of the tool, no need for additional training.

| Tubing With EUE Thread | |||||||

| Pipe OD | Weight | Grade | Wall | ID | Estimated Torque with Ring |

Min Torque with Ring |

Max Torque With Ring |

| In | Lb.ft | In | In | Ft-lb | Ft-lb | Ft-lb | |

| 2-3/8” | 4.7 | L/N80 | 0.19 | 1.994 | 2,375 | 2920 | 3890 |

| 4.7 | P110 | 0.19 | 1.994 | 2,375 | 3530 | 4700 | |

| 2-7/8” | 6.5 | L/N80 | 0.217 | 2.441 | 2,875 | 3440 | 4580 |

| 6.5 | P110 | 0.217 | 2.441 | 2,875 | 4330 | 5770 | |

| 3- 1/2” | 9.3 | L/N80 | 0.254 | 2.992 | 3,500 | 3970 | 5290 |

| 9.3 | P110 | 0.254 | 2.992 | 3,500 | 5220 | 6960 | |

| 4” | 11 | L/N80 | 0.254 | 3.476 | 4,000 | 5220 | 6960 |

| 11 | P110 | 0.254 | 3.476 | 4,000 | 6840 | 9120 | |

| 4- 1/2” | 12.75 | L/N80 | 0.254 | 3.958 | 4,500 | 6800 | 9070 |

| 12.75 | P110 | 0.254 | 3.958 | 4,500 | 8750 | 11600 | |

| Casing with BTC Thread | |||||||

| Pipe OD | Weight | Grade | Wall | ID | Estimated Torque with Ring |

Min Torque with Ring |

Max Torque With Ring |

| In | Lb.ft | In | In | Ft-lb | Ft-lb | Ft-lb | |

| 4- 1/2” | 11.6 | J-55 | 0.25 | 4 | 4,500 | 5,513 | 8,046 |

| K-55 | 0.25 | 4 | 4,500 | 5,513 | 8,046 | ||

| L-80 | 0.25 | 4 | 4,500 | 5,974 | 9,658 | ||

| C-95 | 0.25 | 4 | 4,500 | 6,250 | 10,626 | ||

| P- 110 | 0.25 | 4 | 4,500 | 6,527 | 11,593 | ||

| 13.6 | J-55 | 0.29 | 3.92 | 4,500 | 5,748 | 8,869 | |

| L-80 | 0.29 | 3.92 | 4,500 | 6,316 | 10,855 | ||

| C-95 | 0.29 | 3.92 | 4,500 | 6,656 | 12,047 | ||

| P- 110 | 0.29 | 3.92 | 4,500 | 6,997 | 13,238 | ||

| 5- 1/2” | 17 | J-55 | 0.304 | 4.892 | 5,500 | 7,385 | 9,427 |

| K-55 | 0.304 | 4.892 | 5,500 | 7,385 | 9,642 | ||

| L-80 | 0.304 | 4.892 | 5,500 | 8,242 | 13,712 | ||

| N-80 | 0.304 | 4.892 | 5,500 | 8,242 | 13,712 | ||

| P- 110 | 0.304 | 4.892 | 5,500 | 9,271 | 18,853 | ||

| 20 | L-80 | 0.361 | 4.778 | 5,500 | 8,969 | 17,347 | |

| N-80 | 0.361 | 4.778 | 5,500 | 8,969 | 17,347 | ||

| C-95 | 0.361 | 4.778 | 5,500 | 9,620 | 20,599 | ||

| P- 110 | 0.361 | 4.778 | 5,500 | 10,270 | 23,851 | ||

| 23 | L-80 | 0.415 | 4.67 | 5,500 | 9,642 | 20,711 | |

| N-80 | 0.415 | 4.67 | 5,500 | 9,642 | 20,711 | ||

| C-95 | 0.415 | 4.67 | 5,500 | 10,419 | 24,594 | ||

| P- 110 | 0.415 | 4.67 | 5,500 | 11, 196 | 28,478 | ||

| 7” | 23 | J-55 | 0.317 | 6.366 | 7,000 | 9,632 | 16,211 |

| K-55 | 0.317 | 6.366 | 7,000 | 9,632 | 16,211 | ||

| L-80 | 0.317 | 6.366 | 7,000 | 10,828 | 20,397 | ||

| N-80 | 0.317 | 6.366 | 7,000 | 10,828 | 20,397 | ||

| P- 110 | 0.317 | 6.366 | 7,000 | 12,263 | 25,421 | ||

| 26 | J-55 | 0.362 | 6.276 | 7,000 | 10, 176 | 18, 117 | |

| L-80 | 0.362 | 6.276 | 7,000 | 11,620 | 23, 171 | ||

| N-80 | 0.362 | 6.276 | 7,000 | 11,620 | 23, 171 | ||

| C-95 | 0.362 | 6.276 | 7,000 | 12,486 | 26,202 | ||

| P- 110 | 0.362 | 6.276 | 7,000 | 13,353 | 29,235 | ||

| 29 | K-55 | 0.408 | 6.184 | 7,000 | 10,725 | 20,038 | |

| L-80 | 0.408 | 6.184 | 7,000 | 12,418 | 25,964 | ||

| N-80 | 0.408 | 6.184 | 7,000 | 12,418 | 25,964 | ||

| C-95 | 0.408 | 6.184 | 7,000 | 13,434 | 29,520 | ||

| P- 110 | 0.408 | 6.184 | 7,000 | 14,450 | 33,076 | ||

| 32 | J-55 | 0.453 | 6.094 | 7,000 | 11,254 | 21,890 | |

| L-80 | 0.453 | 6.094 | 7,000 | 13, 188 | 28,658 | ||

| N-80 | 0.453 | 6.094 | 7,000 | 13, 188 | 28,658 | ||

| C-95 | 0.453 | 6.094 | 7,000 | 14,348 | 32,719 | ||

| P- 110 | 0.453 | 6.094 | 7,000 | 15,508 | 36,779 | ||

| 9-5/8” | 36 | J-55 | 0.352 | 8.921 | 9,625 | 15,768 | 30,713 |

| K-55 | 0.352 | 8.921 | 9,625 | 15,768 | 30,713 | ||

| L-80 | 0.352 | 8.921 | 9,625 | 17,684 | 40,297 | ||

| N-80 | 0.352 | 8.921 | 9,625 | 17,684 | 40,297 | ||

| C-90 | 0.352 | 8.921 | 9,625 | 18,451 | 44, 132 | ||

| P- 110 | 0.352 | 8.921 | 9,625 | 19,985 | 51,799 | ||

| 40 | J-55 | 0.395 | 8.835 | 9,625 | 13,048 | 34,231 | |

| K-55 | 0.395 | 8.835 | 9,625 | 13,048 | 34,231 | ||

| L-80 | 0.395 | 8.835 | 9,625 | 14, 166 | 45,415 | ||

| N-80 | 0.395 | 8.835 | 9,625 | 14, 166 | 45,415 | ||

| C-90 | 0.395 | 8.835 | 9,625 | 14,616 | 49,888 | ||

| 43.5 | K-55 | 0.435 | 8.755 | 9,625 | 13,372 | 37,473 | |

| L-80 | 0.435 | 8.755 | 9,625 | 14,638 | 50, 131 | ||

| N-80 | 0.435 | 8.755 | 9,625 | 14,638 | 50, 131 | ||

| C-90 | 0.435 | 8.755 | 9,625 | 15, 144 | 55, 194 | ||

| P- 110 | 0.435 | 8.755 | 9,625 | 15877 | 62,521 | ||

| 47 | L-80 | 0.472 | 8.681 | 9,625 | 15,071 | 54,455 | |

| N-80 | 0.472 | 8.681 | 9,625 | 15,071 | 54,455 | ||

| C-90 | 0.472 | 8.681 | 9,625 | 15,631 | 60,059 | ||

| P110 | 0.472 | 8.681 | 9,625 | 16,752 | 71,266 | ||

| 53.5 | L-80 | 0.545 | 8.535 | 9,625 | 15,913 | 62,879 | |

| N-80 | 0.545 | 8.535 | 9,625 | 15,913 | 62,879 | ||

| C-90 | 0.545 | 8.535 | 9,625 | 16,579 | 69,535 | ||

| P- 110 | 0.545 | 8.535 | 9,625 | 17,910 | 82,849 | ||

| 13-3/8” | 54.5 | J-55 | 0.38 | 12.615 | 13,375 | 19,337 | 59,616 |

| K-55 | 0.38 | 12.615 | 13,375 | 19,337 | 59,616 | ||

| M-65 | 0.38 | 12.615 | 13,375 | 20, 177 | 68,023 | ||

| L-80 | 0.38 | 12.615 | 13,375 | 21,438 | 80,635 | ||

| N-80 | 0.38 | 12.615 | 13,375 | 21,438 | 80,635 | ||

| 61 | J-55 | 0.43 | 12.515 | 13,375 | 20, 141 | 67,662 | |

| L-80 | 0.43 | 12.515 | 13,375 | 20, 141 | 67,662 | ||

| M-65 | 0.43 | 12.515 | 13,375 | 21, 128 | 77,532 | ||

| L-80 | 0.43 | 12.515 | 13,375 | 22,609 | 92,338 | ||

| N-80 | 0.43 | 12.515 | 13,375 | 22,609 | 92,338 | ||

| 68 | J-55 | 0.48 | 12.415 | 13,375 | 20,939 | 75,644 | |

| K-55 | 0.48 | 12.415 | 13,375 | 20,939 | 75,644 | ||

| M-65 | 0.48 | 12.415 | 13,375 | 22,072 | 86,965 | ||

| L-80 | 0.48 | 12.415 | 13,375 | 23,770 | 103,948 | ||

| N-80 | 0.48 | 12.415 | 13,375 | 23,770 | 103,948 | ||