Chemical Composition & Equivalent Grades

|

Standard |

Grade |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

|

ASTM A29 |

4130 |

0.28-0.33 |

0.40-0.60 |

0.035 |

0.040 |

0.15-0.35 |

0.80-1.10 |

0.15-0.25 |

|

EN10250 |

25CrMo4/ |

0.22-0.29 |

0.60-0.90 |

0.025 |

0.035 |

≦0.40 |

0.90-1.2 |

0.15-0.30 |

|

JIS G4105 |

SCM430/ |

0.28-0.33 |

0.60-0.85 |

0.030 |

0.030 |

0.15-0.35 |

0.90-1.2 |

0.15-0.30 |

Mechanical Properties

|

Tensile strength,

ultimate |

560 MPa |

|

Tensile strength,

yield |

460 MPa |

|

Modulus of

elasticity |

190-210 GPa |

|

Bulk modulus

(Typical for steel) |

140 GPa |

|

Shear modulus

(Typical for steel) |

80 GPa |

|

Poissons ratio |

0.27-0.30 |

|

Elongation at

break (in 50 mm) |

21.50% |

|

Reduction of area |

59.6 |

|

Hardness, Brinell |

217 |

|

Hardness, Knoop

(Converted from Brinell hardness) |

240 |

|

Hardness,

Rockwell B (Converted from Brinell hardness) |

95 |

|

Hardness,

Rockwell C (Converted from Brinell hardness) |

17 |

|

Hardness, Vickers

(Converted from Brinell hardness) |

228 |

|

Machinability

(Annealed and cold drawn.) |

70 |

Forging

AISI 4130 steel should be forged between 1230 and 950 º C

(2250 and 1750 º F). The lower the finishing temperature from forging, the

finer the grain size will be. If the 4130 alloy steel is forged at a too low

temperature, there is the risk of the formation of a non-uniform structure in

certain areas of the forged part, necessitating a normalizing treatment, prior

to further heat treatment.

Fabrication and Heat Treatment

·

Machinability

- AISI 4130 steel can be easily machined using conventional methods. However,

machining becomes difficult when the hardness of the steel is increased.

·

Forming of AISI

4130 steel can be performed in the annealed condition.

·

Welding of AISI

4130 steel can be performed by all commercial methods.

·

Heat Treatment

- SAE steel is heated at 871°C (1600°F) and then quenched in oil. This steel is

usually heat-treated at temperatures ranging from 899 to 927°C (1650 to

1700°F).

·

Forging of AISI

4130 steel can be performed at 954 to 1204°C (1750 to 2200°F).

·

Hot working of

AISI 4130 steel can be done at 816 to 1093°C (1500 to 2000°F).

·

AISI 4130

steel can be cold worked using conventional methods.

·

SAE 4130

steel can be annealed at 843°C (1550°F) followed by air cooling at 482°C

(900°F).

·

Tempering of AISI

4130 steel can be performed at 399 to 566°C (750 to 1050°F), depending on the

desired strength level.

· Hardening of AISI 4130 steel can be done with cold working or heat treatment.

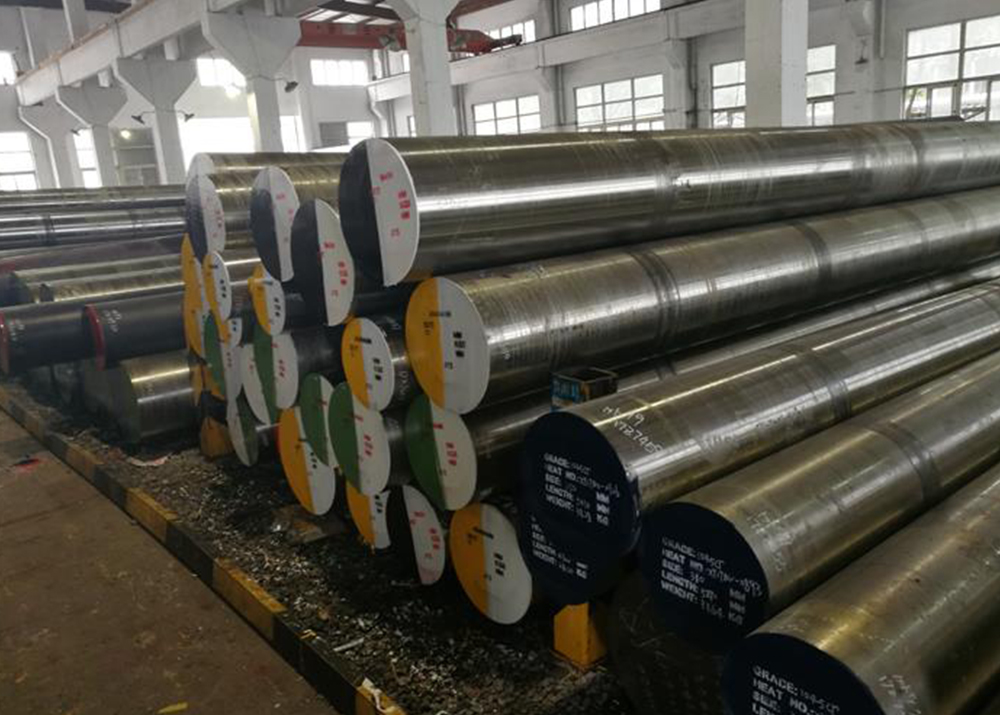

Applications

AISI 4130 steel is an exceptionally tough metal suitable for

manufacturing, welding, cutting, and other high-stress applications in

industry. It has great heat treatment characteristics which impart a high

toughness as well as great workability and machinability. Although most often used

as structural steel, it has more applications as below:

·

Materials for

bearings, vehicle parts, and gears

·

Rock crushing

machinery

·

Resistance

welding products

·

Drill

bits and taps

·

Mills and cutters